Jay Tourigny takes a look at cleaning techniques and which are suited for different applications

Faster and more stable all-fibre networks are quickly replacing more traditional coaxial or copper core cable systems. But, for these fibre networks to effectively handle the ever-growing demand for more speed and capacity, reliability is key.

Network providers must ensure fibre is installed and maintained correctly, especially as fibre connectivity rolls out to more remote or rural areas. This includes ensuring all cable splices and end face connections are perfectly clean prior to network start-up. Clean connections help providers guarantee optimal network operation, uninterrupted connectivity and the high-speed operation their users demand.

In addition, it prevents costly and time-consuming rollbacks to troubleshoot and fix connectivity issues caused by simple connector contamination that could have been easily avoided during the initial installation.

Threat to reliability

Contamination is the number one threat to fibre network reliability. Contamination is defined as a removable impurity on the connector end face and can include anything from lint and fingerprint oils, to moisture or simple dust.

Contamination can cause intermittent signal

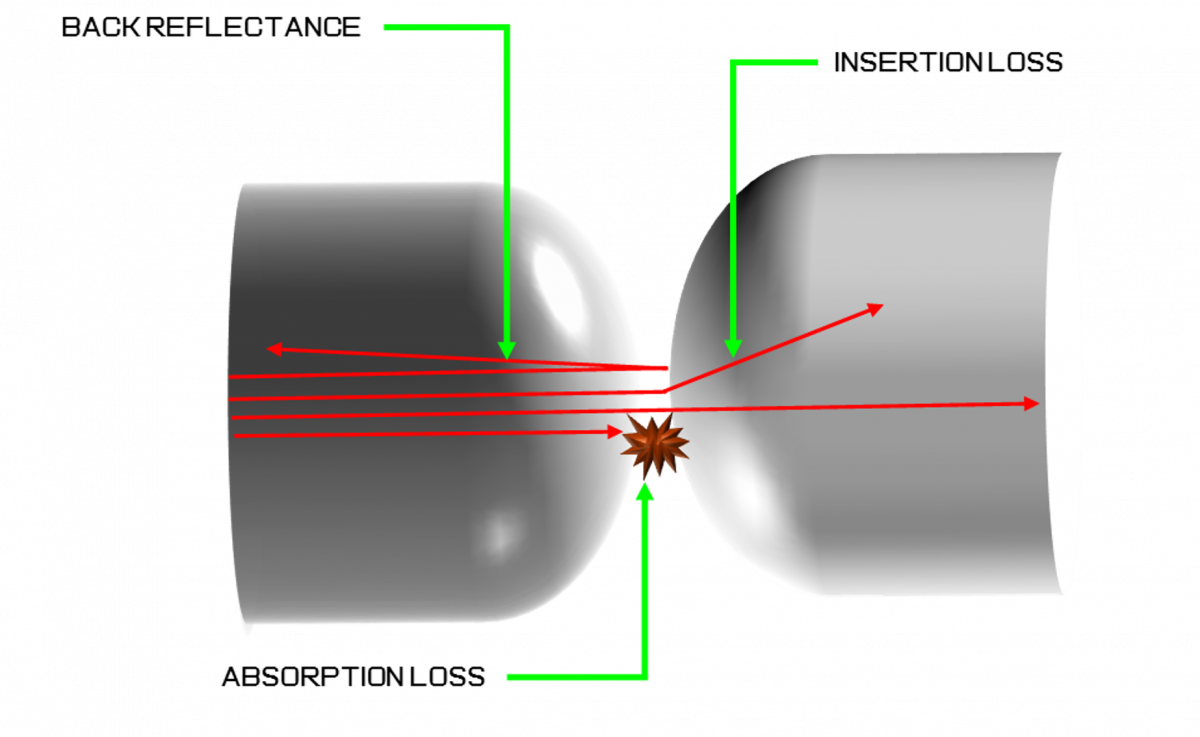

A contaminated end face can potentially block or redirect the light from moving through the fibre cable. This can cause an intermittent signal and, if the contamination is severe enough, permanent damage to the system components and a complete network shutdown.

Dust-based contamination is one of the most common forms of contamination and originates from many sources. Dust comes from vehicle emissions, cable packaging, construction site dirt, contact friction from mating and unmating end faces, and clothing lint.

Dust can even be caused by the fibre cleaning tools themselves. Poorly made foam swabs, lint-prone paper-based wipes, and low-purity cleaning fluids, such as isopropyl alcohol (IPA), can add significant contamination. Therefore, installers should always thoroughly clean both ends of the connector pair before they are mated to ensure clean fibre connections.

The right tool for the job

For the most effective cleaning, it’s important to know which fibre cleaning tool to use. Mechanical clicker-style tools are quick to use and good for applications with light levels of contamination. They can help installers efficiently clean a high-volume of connectors. However, they may not be ideally sized for cleaning termini in hardened connector housings.

Fibre cleaning sticks on the other hand, are specifically engineered to thoroughly clean heavily contaminated end faces or for cleaning connectors mounted in hard-to-clean alignment sleeves.

Because cleaning sticks make good contact with the end-face configuration, they clean the entire end face without the need to disassemble the connector or adapter. They give the largest effective cleaning region on the entire surface eliminating problems associated with contaminants migrating into the signal path.

A cleaning stick should be engineered specifically to match the configuration and size of the end-face and be non-linting for optimal cleaning. When using the stick, it is important to only rotate in one direction; typically six rotations in one direction is enough to remove any contamination. Importantly, only use one stick per-end-face to avoid cross-contamination.

Wipe out

If using a wipe instead of a cleaning tool or stick, insist on high-grade wipes that do not lint or generate a static charge for cleaning fibre end faces. Optical-grade wipes are soft and will not scratch delicate ceramic or composite ferrule end faces. They are also highly absorbent to completely wipe away contamination without leaving residue or lint behind. It is also important to ensure the wipes you use are housed in sealed packages. This helps to keep them pure and clean prior to use.

The addition of a cleaning fluid helps boost the cleaning tools’ effectiveness by creating a dissipative path to remove any static charge. Wet to dry cleaning, as it is known, dissipates the triboelectric charges on the end faces and prevents dust from adhering to them. Especially in the contact zone where it can do the most harm. Wet to dry cleaning can be used with any tool you choose, no matter if it is a clicker tool, stick or wipe.

However, IPA or water are not recommended fibre cleaning fluids. Both are hard to find in high purity packaging. They are also slow to dry and are nearly impossible to keep clean and uncontaminated during day-to-day use. A specially-engineered, optical-grade cleaning fluid dispensed from a hermetically sealed container is a better option. It readily removes the contaminant but also eliminates the triboelectric charges that attract dust particles and causes them to stick to a connector end face.

Time savings

Quick-drying optical-grade fibre cleaning fluid helps reduce cleaning time. It also prohibits atmospheric moisture from being attracted to the fluid, further reducing possible contamination. An added bonus is that it is non-flammable and non-hazardous, making it safe to store and easy to transport to a job site.

When cleaning fibre, always inspect the termini on both ends of a connector pair first to visually identify the level of contamination. Then, using the wet-to-dry cleaning method, remove the contamination and dissipate electro-static charges in one step.

Using the wet-to-dry cleaning method in combination with the best tool for the job helps installers and fibre network providers ensure their networks stay reliable and trouble-free. For those looking for help in choosing the best fibre cleaning tools and methods, it’s best to consult with a vendor specialising in fibre optic cleaning. They can recommend the tools and procedures that work best.

Jay Tourigny is senior vice president at MicroCare, which offers Sticklers brand cleaning solutions