When the world’s first transatlantic cable failed in 1858 – just three weeks after it had been inaugurated with a congratulatory telegram from Queen Victoria to US President James Buchanan – it took eight years until a replacement was operational. The cable, made of copper wires insulated with natural latex from the gutta-percha tree, probably had manufacturing faults and burnt out when its electric load was cranked up to compensate for rapidly deteriorating signal strength.

When the Tohoku earthquake and tsunami devastated Eastern Japan on 11 March 2011, it killed more than 15,000 people and destroyed roads, bridges and nuclear reactors. It also damaged around half the transpacific cables connecting the country with the rest of the world. Within just a few days, ships had started lowering remotely operated vehicles (ROV) into the sea to repair the twisted and torn fibre optic cables.

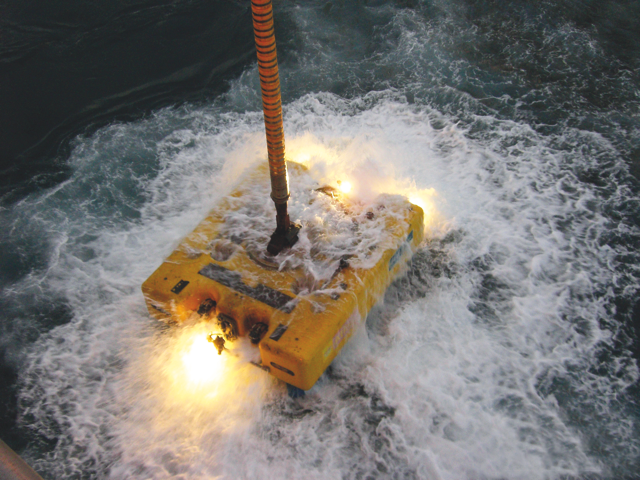

To repair fibre-optic cables at depths of 2,500m, the Kokusai Cable Ship Company Ltd (KCS), a Japanese cable installer, turned to the Marcas IV produced by a UK company, Soil Machine Dynamics. The company is a leading manufacturer of remote intervention equipment, operating in hazardous environments worldwide.

With a particular focus on subsea engineering, SMD has become a major designer and manufacturer of specialist subsea ROVs worldwide. Marcas IV, and similar high-tech ROVs, have ‘multifunctional capabilities – where one asset can do multiple tasks, working with soft ground and hard ground cables,’ says Graeme Walker, SMD’s sales manager.

In May, Global Marine Systems (GMS), a global supplier of submarine cable installation, maintenance and repair services, launched the DXr1 camera – an x-ray camera to monitor the quality of repairs of a cable joint. Its outstanding feature is that it uses digital imaging technology in place of traditional film. The camera allows a real-time review, so that it is possible to ‘make sure, right there on the ship, whether the cable is connected properly,’ says Anne Dellos LeBoutillier of GMS.

Also reducing repair time is new technology to locate and retrieve broken cable ends, for example with new grapnel hook technology that makes it possible to grab and cut cable ends simultaneously. This reduces repair time by a day or more, says Andy Palmer-Felgate, project manager in charge of cable repairs at US telecoms giant Verizon, a company that owns or leases more than 80 cables worldwide.

The Atlas 1 is a working ROV, designed for cable maintenance, post-lay, and inspection roles. With 300kW of installed power, Atlas 1 has a range down to 2,000m under water

The Tyco Reliance cable-laying vessel (TE SubCom was formerly called Tyco)

Below right: Submarine cable landing on the coast of Oregon, USA