Scientists from the Fraunhofer-Gesellschaft and Max-Planck-Gesellschaft are working together on processes for manufacturing preforms for hollow-structure fibres with new geometrical shapes.

In the project, known as ‘Laser-generated three-dimensional photonic components’ (LAR3S), the partners will pool their experience to expand process knowledge and develop new technologies for manufacturing various 3D structures with lasers. The Max Planck Institute for the Science of Light (MPL), the Fraunhofer Institute for Laser Technology ILT and the Fraunhofer Institute for Silicate Research ISC are involved.

Project LAR3S aims to take a new approach to producing 3D photonic components with lasers, focusing on selective laser-induced etching and inverse laser drilling. A key goal is to achieve processes and procedures that can be automated.

To process the inside of glass, for example, laser radiation is used to penetrate the material, making it possible to process a wide variety of transparent materials with extensive geometrical freedom in all three dimensions. The challenge lies is in the details – in order to achieve crack- and fracture-free results, research must understand the material properties and machining processes in detail.

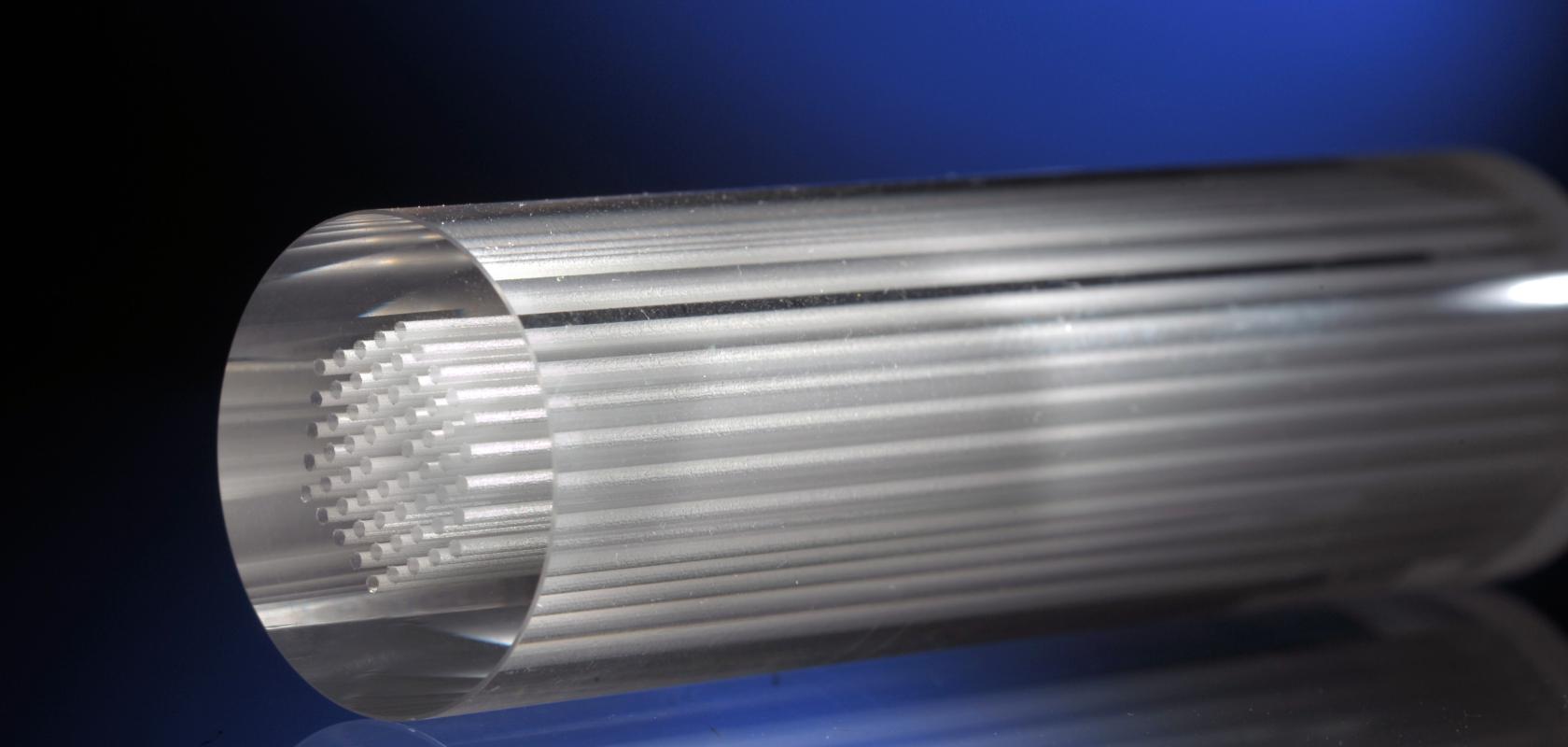

Hollow glass fibre is generally achieved by having glass rods or tubes stacked together and drawn to length, known as the stack-and-draw process. In telecoms applications, hollow-core fibres with gas or a vacuum in favour of traditional cores can be used to enable properties such as faster light speed and reduced sensitivity to environmental variations.

The construction of structured fibres is usually limited to a hexagonal shape when the stack-and-draw method is used. Engineers at Fraunhofer ILT are continuing to develop a patented process – inverse laser beam drilling – with which more complex and thus potentially more advantageous structures can be manufactured completely automatically. In this process, the laser beam is focused through a transparent component onto the rear side and moved over the surface to be ablated with a scanner, effectively drilling a hole backwards into the glass. This allows almost any structures with large aspect ratios to be introduced into the fibre blank, and other transparent materials are also achievable. In the future, the structures will be calculated on the computer with artificial intelligence and directly manufactured with the laser.

Fraunhofer ISC’s involvement brings competence in process control to the project: removing the ablated residual materials from the boreholes. The project partners are optimising the laser parameters and developing physical or chemical methods for process optimisation. The goal is to create structures with tailored dispersive properties in fibre preforms more than 200mm long.

In addition, for selective laser-induced etching, focused ultrashort-pulsed laser radiation is used to structure the volume and surfaces of a transparent material crack-free, changing its chemical properties so that it can later be selectively etched. When the focus is deflected in the workpiece, contiguous areas are modified, which can be removed in the second process step by wet chemical etching. This two-part process also provides its users with a high degree of geometrical freedom. The project partners want to optimise the process for new geometrical shapes in the manufacture of laser microresonators. Such structures can be used in telecommunications and quantum technology.

The project is funded by the Fraunhofer Max Planck Cooperation Program and it will run for three years.