Researchers at Southampton’s Optoelectronics Research Centre have successfully manufactured an 11-km length of hollow-core photonic bandgap fibre, a special type of fibre that until now has usually been made in lengths of hundreds of metres.

Hollow-core fibres, where light travels mainly in air, are interesting because they could reduce latency by about 30 per cent compared to standard solid-silica optical fibres.

The Southampton work, which is the result of a research programme funded by both the UK Engineering and Physical Sciences Research Council (EPSRC) and European Union FP7 programme, brings such fibres much closer to practical application.

“Hollow-core photonic bandgap fibre has only had niche applications up until now because it was thought that it could not be manufactured in lengths suitable for telecoms applications,” said Dr Marco Petrovich, a senior member of the ORC team. “Not only have we successfully made a photonic bandgap fibre in a suitable length, we have also engineered it to have the right properties for telecoms applications.”

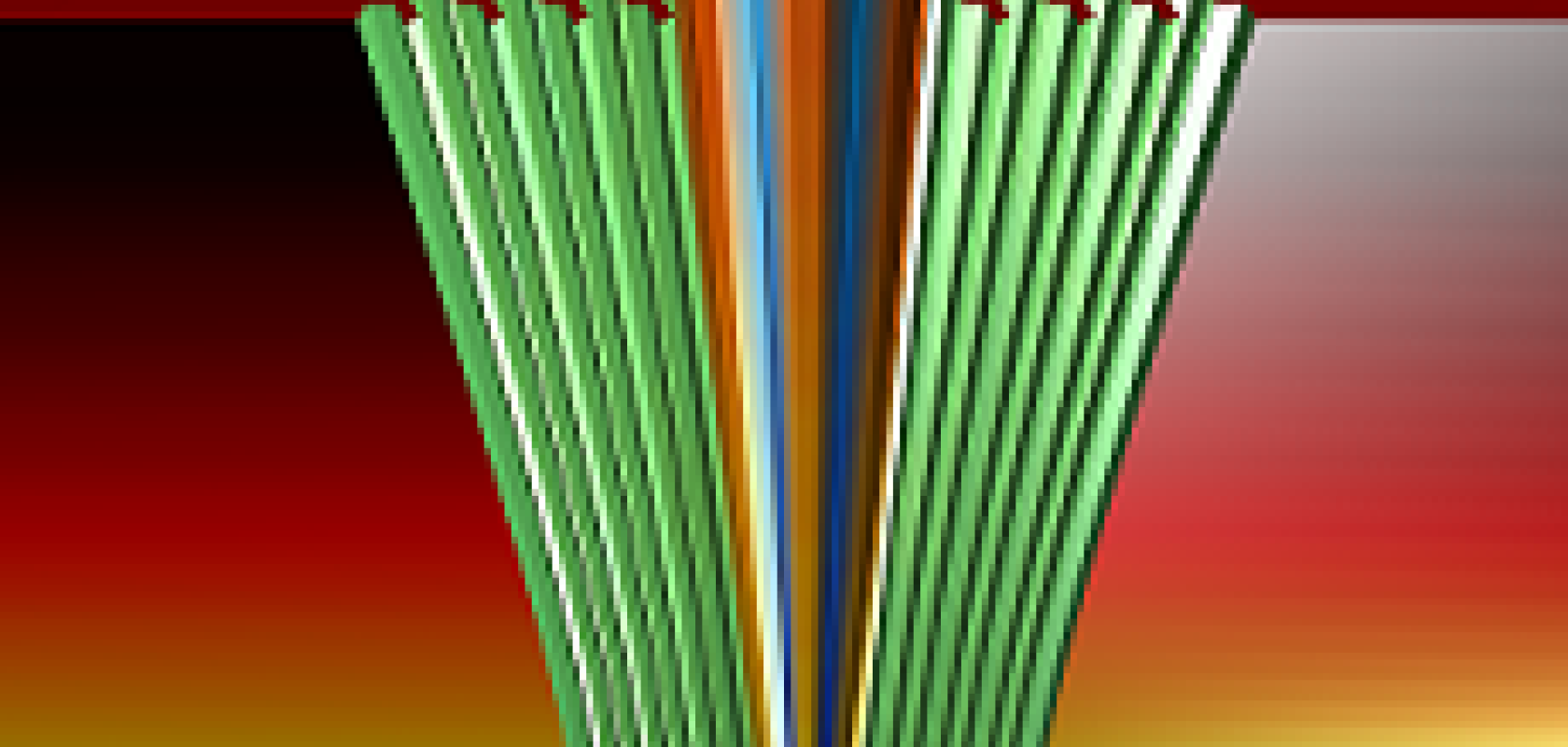

The fibre, which supports more than 200nm bandwidth with a longitudinally uniform loss of approximately 5dB/km at 1560nm, has a 19-cell hollow core and 5-cell deep cladding ring structure. It was fabricated using a conventional two-stage stack-and-draw technique.

Petrovich and his colleagues then demonstrated that the fibre can support error-free, low-latency, direct-detection 10Gb/s transmission across the entire C-band, the wavelength band used for long-distance telecommunications.

“We demonstrated data transmission at 10Gb/s along a 11km span using direct detection, showing only minor penalties and achieving an estimated >15μs latency reduction relative to standard fibre,” said Petrovich. “Our numerical models of the fibre drawing process give us confidence that much longer fibre yields are feasible through further scaling of the process, and that much lower loss fibres should ultimately be possible.”

Manufacturing long lengths of photonic band gap fibre is notoriously difficult because unlike conventional fibres, whose properties depend on the materials used to make them, the properties of photonic bandgap fibres depend on their structure. The nodes and struts that give photonic bandgap fibre its properties are usually on a sub-micron scale with many even just a few nanometres in size.

“Any small change in these structures can change the properties along the fibre,” said Petrovich. “We have shown that our fibre’s properties are consistent along its entire length.”

The breakthrough was made possible due to an improved understanding of fibre properties deriving from various new numerical and experimental fabrication and characterisation tools recently developed by the team of researchers.

The longest length of hollow-core fibre previously reported was 2.75km, a distance that would encompass most intra data centre requirements. OFS Laboratories and Coriant reported 100G transmission over this length of fibre in an invited paper at the Optical Fiber Communication 2015 conference in March (paper M3D.4).