Fibre optic infrastructures are becoming more widespread in a number of markets and applications. These include simple point-to-point security systems, Ethernet mesh networks and high-performance, high-bandwidth video transport and switching systems for the A/V and broadcast markets. As this fibre infrastructure spreads, a variety of fibre interconnect solutions are evolving to meet new needs. These may be as simple as fibre connectors for direct connectivity to patch panels or transmission equipment, or as complex as multi-fibre connectors used in rugged, hostile outdoor environments. Clean, reliable optical connectors are paramount in building a reliable, high-performance fibre infrastructure that lasts for years.

Growth of Fibre Optics for High Reliability

As more governments, companies, organisations and industries demand increased bandwidth, more data and better quality audio/video, the use of fibre optics around the globe has grown rapidly. That need for more and better data means more fibre optic cable and more high-density, reliable optical connectors.

Rugged applications, such as government, military and broadcast, are making the transition from lower bandwidth, larger core multimode fibres to more efficient single-mode fibre with its much smaller core or mode field diameter (light carrying portion of the fibre) and extremely high bandwidth. High bandwidth HD video, and the more recent Ultra HD or 4K video, require the use of single-mode fibre for long-distance applications. Indoor A/V and broadcast applications include board rooms, studios and control rooms, pre- and post-production, airports, and concert and entertainment venues. More rugged outdoor applications include defence and security communications, sporting events, video transport, studio-to-OB van interconnects, rental and staging applications. All of these applications require high-reliability fibre optic cable and connectors. It is important to choose the proper connectors for the specific environment and application to minimise their cleaning/testing/maintenance and ensure the highest reliability as well as the minimum amount of system downtime.

As video resolution continues to increase and the number of signals on one fibre continues to grow, it becomes imperative to incorporate single-mode fibre into new system designs. Using single-mode fibre poses new concerns for the fibre connector end surface condition and cleanliness. When working and properly maintained, fibre has significantly greater bandwidth and is more reliable than copper.

Companies moving to fibre optics benefit by being able to send high-definition video over long distances without losing quality, plus send data at higher speeds than through traditional copper wiring. Unlike traditional copper infrastructure, a single fibre can transmit any signal from simple contact closures to audio, data, NTSC video and now HD & Ultra HD video without needing to change the fibre. In fact, all of these signals can be transmitted over the same fibre simultaneously without any loss of performance. This has significant implications for communications, remote monitoring and other data-intensive applications. Simply stated, fibre optics carries significantly more data over greater distances than copper.

One of the keys to ensuring a quality, high-reliability fibre infrastructure is to use high-performance, rugged optical connectors that can easily be cleaned and maintained. There are two major approaches for addressing cleaning issues for multi-fibre rugged connectors that are made up of common indoor-use style components:

- Expanded beam uses bigger connectors to reduce the need for cleaning, but the trade-off is that you get reduced optical performance when you integrate them into your solution.

- Encapsulated and easily cleanable rugged fibre optic connectors that are easy to clean and still maintain the required high optical performance.

If maintaining optical performance is essential to your application, you will want to examine fibre optic connectors that are encapsulated and designed to be cleaned.

Why Cleaning Matters

Cleaning is the biggest challenge in fibre optic cable technology today. Costs of cleaning include limiting the life of the fibre optic cable when the ferrule is damaged or broken when connecting. Losing a single ferrule can mean losing the whole connector, so selecting a connector that is easy to clean can be worth the total cost of the cable.

Fibre optic connectors require more attention than traditional electrical connectors because they can more easily be damaged. Companies looking to invest in fibre optics should understand the role that cleaning plays in the application at hand, and learn the best methods of cleaning their particular connector. This can play a large role in decisions when fibre optics will be mated/unmated in rugged conditions.

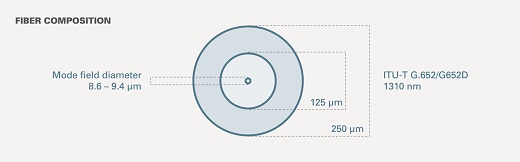

Figure 1 shows the composition of a single-mode fibre (core, cladding, buffer). The light-carrying portion of the fibre (core) is generally specified by its mode field diameter (MFD) and has a diameter of approximately 9 μm. These fibres have a cladding diameter of 125 μm, while the protective buffer has a diameter of 250 μm. As illustrated, when compared to the entire surface of the fibre, the core or MFD is quite small. It is crucial that this surface of the fibre be kept clean and free of dirt, defects, scratches, etc.

Figure 1

Since the fibre contacts, or ferrules, in the connector make physical contact with one another within the connector’s alignment sleeve, any contamination or dirt on one of the ferrules can easily be transferred to the mating ferrule, further complicating the cleaning process. This also runs the risk of causing physical damage to the fibre’s end face.

Because the data is transmitted through the small 9 μm core of the single-mode optical fibre, a very small amount of dirt or residue may significantly increase the connector’s attenuation and weaken the signal. System installers, integrators and others just starting to work with fibre will soon realize that a single-mode fibre optic connector is much more sensitive to dust, dirt and other contaminants than standard electrical connectors or even multimode optical connectors (due to their much larger core diameter). And of course, the place where dirt, dust and contaminants enter the system is at the connector interfaces.

The proper inspection and cleaning of fibre end faces is critical to the performance and life of any fibre optic system. Failure to apply proper cleaning procedures each time a connector is mated can directly impact the quality of the system’s performance. Each time a fibre optic connector is mated, both the plug and receptacle must be cleaned and, when possible, inspected to ensure that nothing – not even a speck of dust – remains. Bulkhead connectors on transmission equipment and patch panels, for example, can easily be contaminated by dirt from the mating cable or patch cord connector. These recessed connectors, however, can be more challenging to clean and evaluate, since it may be necessary to clean the ferrule by accessing it through the alignment sleeve.

The replacement cost in terms of time and money for one of these multi-contact connectors can be quite substantial and may result in expensive system down-time. Since these multi-contact connectors are difficult if not impossible to be repaired in the field, it would be necessary to replace the cable.

Safety First

It is good practice to follow the following safety recommendations when working with and inspecting fibres:

- When a power meter is available, it is recommended that the output power from each fibre be checked to ensure that there is no light present.

- Whenever possible, use a video scope for eye protection and improved visual monitoring to inspect fibre connector end faces.

- If you are using a handheld optical magnifier to inspect fibre connectors, ensure that it has an internal filter and a magnification of at least 200x for proper viewing of the fibre end surface.

- In addition, wear safety glasses and make sure that the cable is disconnected at both ends, or that the card or pluggable receiver is removed from the chassis.

It is important to take these precautions in the field, no matter which connectors you are using. Since many fibres carry bi-directional signals, it is imperative to ensure that both ends of the fibre are disconnected from the transmission equipment.

Field & Maintenance Cleaning

Most companies that install fibre optics on a regular basis have their own set of installation and cleaning instructions. They all have one thing in common: multiple steps that require the installer to clean, inspect and test both the plug and receptacle, with instructions to go from one cleaning method to another if (when) the first and second approaches do not work. Generally, connector manufacturers will publish guidelines for cleaning their connectors and may recommend specific cleaning and ferrule inspection tools to ensure that they are cleaned properly with minimal risk of damage.

There are two places where cleaning requirements come into play: in the field (mobile/remote) and in-house (fixed). The troubleshooting lists differ based on the likelihood of contamination and the cleaning materials available. These cleaning techniques are simplified with the use of rugged, sealed connectors.

The usually lengthy and detailed field cleaning process may contribute to slower-than-expected fibre optic growth in rugged conditions. However, attention paid to new connector designs will reduce the time required and difficulty in cleaning. If you have a rugged, sealed connector like the new Fischer FiberOptic connector, field cleaning is simplified by rinsing with any clean, available water source, and drying the ferrules with clean canned air followed by ferrule face cleaning with an IBC cleaner or equivalent. This approach only applies to connectors sealed to IP67/68 standards where water intrusion is eliminated. The water wash can be done in the field to remove dirt around the outside and inside of connectors without fear of introducing additional contaminants. The following ‘water wash’ procedure is applicable to the Fischer FiberOptic connector:

- Place the connector under running tap water until everything is cleaned as shown in the photos in Figure 2 below.

- Remove the sleeve holder with tweezers or small pliers.

- Repeat the tap water operation over the exposed contacts, if needed.

- Dry the contacts and connector by spraying canned air on it.

- Dry the sleeve holder by spraying canned air on it.

- Insert the IBCTM Brand Cleaner on all contacts and perform one click/cleaning per contact.

- Reassemble the sleeve holder in any of the four positions, being careful to align the contacts with the alignment sleeves in the holder.

- Always clean both sides of the connector, as dirt on one contact may transfer to the clean one which would then contaminate both sides.

Figure 2: Water wash for the Fischer FiberOptic connector

The Fischer FiberOptic Series solution allows for easy field cleaning because of a unique sealing solution and removable parts.

This approach minimises the time it takes to field clean and inspect a fibre optic connector, making it more efficient and effective.

For fixed locations, you can take advantage of ultrasonic cleaning to maintain your connectors (see Figure 3 below):

- Put your connector under running tap water until everything is entirely cleaned.

- Remove the sleeve holder with tweezers or small pliers.

- Put the connector and the sleeve holder for ~1 minute in the ultrasonic bath, which has been filled with isopropyl alcohol.

- When done, dry the contacts and connector by spraying canned air on it.

- Dry the sleeve holder by spraying canned air on it.

- Reassemble the sleeve holder.

- Slightly grease the plug sealing plan to recover full sealing capabilities.

Figure 3: Maintenance cleaning for the Fischer FiberOptic connector

The more difficult and complicated the preparation and cleaning procedures, the longer it takes and the more expensive it becomes. In addition, connectors that are difficult to clean generally require more expensive cleaning tools and may require more experienced personnel. In terms of system integration, going ‘live’, and maintenance, the simpler the cleaning procedure and required tools, the faster the connectors can be prepped and integrated. This, obviously, saves both time and money.

Selecting Fibre Optic Connectors

Methods for cleaning fibre optic connectors continue to evolve with the innovation of new connectors for rugged environments. This new approach allows companies to consider moving fibre to environments that would not be considered only a few years ago.

As companies continue to innovate in connectors and cleaning materials, it is important that designers and project managers select their connectors properly. Considerations that are part and parcel of connector selection include such factors as costs associated with fibre optic cable/connector deployment, field and maintenance requirements and overall system reliability. With proper selection and care, these fibre optic connectors will perform flawlessly for years in your fibre cable infrastructure.

White Paper on ‘Trends in Fibre Optic Connector Cleaning’

Fischer Connectors’ white paper addresses the importance of cleaning and maintaining optical connectors for optimal performance and reliability. The paper also addresses new approaches to rugged fibre optic connectors to simplify the field-cleaning and inspection process.